TESTING METHOD'S AFTER POWDER COATING

IMPACT TEST

IMPACT TEST

The Impact test Deforms a Sample Panel in Order to Test the Adhesion of The Powder Coating. The Powder Coated Finish Should Not Crack or lose Adhesion to the Substrate in the Impacted Area.

BENDING TEST

BENDING TEST

This Test is Used to Evaluate the Elasticity of Coatings. In this test, Coated Plates Will be Bent Around a Conical or Cylindrical Metal Axis. In the Conical Bend Test, Various Bending Diameters are Continully Tested But in The Cylindrical bend test, Various Diameters are Discontinously.

DFT TEST (Dry Film Thickness)

DFT TEST (Dry Film Thickness)

Dry Film Thikness (DFT) is the Thickness of a Coating as MEasures above the Substrate. This can Consist of a Single Layer or Multiple Layers.

DFT is Measured for Cured Coating (After the Coating Dries)

BOILING TEST

BOILING TEST

The Boiling Test is used to Check the Pre-Treatment of a Coating, Sample Plates ate Placed in Boiling Demineralized Water, No Bubbles or Detachments Should be Visible.

SALT SPRAY TEST

SALT SPRAY TEST

The Salt Spray Test (or Salt Fog Test) is a Standardized and Popular Corrosion Test Method, Used to Check Corrosion Resistance of Materials and Surface Coating.

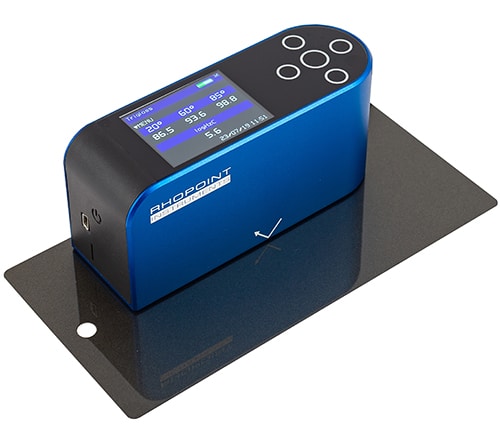

GLOSS LEVEL CHECK

GLOSS LEVEL CHECK

The Gloss of a Finished Powder Coated Part is Validated by Measuring the Specular Reflaction of its Surface.

PENCIL TEST

PENCIL TEST

The Pencil Hardness Test, Uses the Varying Hardness Values of Graphite Pencils to Evaluate a Coating's Hardness.

MEK TEST

MEK TEST

This Test is Used to Ensure Proper Cure of The Powder Coating to the Substrate.

TTR REPORT FOR CURING OVEN

TTR REPORT FOR CURING OVEN

Proper Oven Calibration is Essential to Consistency and Quality Control in a Wide Range of Industries, and if you Fail to Properly Calibrate oven Tempurature, you run the risk of Improper Curing, Incomplate Drying, and a Costly Waste of Energy.

CROSS CUT

CROSS CUT

The cross-cut test is a method of determining the resistance of paints and coatings to o separation from substrates by utilizing a tool to cut a right angle lattice pattern into the coating, penetrating all the way to the substrate.